LANTYTO® Machine

| Model | Shearing Thickness | Shearing Width | Number of Strokes | Stroke of Rear Stopper | Shearing Angle |

Bench Height |

Motor Power |

| mm | mm | time/min | mm | ° | mm | kw | |

| Q11Y 6×2500 | 6 | 2500 | 16~35 | 20~600 | 30′-1°30′ | 800 | 7.5 |

| Q11Y 6×3200 | 6 | 3200 | 14~35 | 20~600 | 30′-1°30′ | 800 | 7.5 |

| Q11Y 6×4000 | 6 | 4000 | 10~30 | 20~600 | 30′-1°30′ | 800 | 7.5 |

| Q11Y 6×5000 | 6 | 5000 | 10~30 | 20~800 | 30′-1°30′ | 900 | 11 |

| Q11Y 6×6000 | 6 | 6000 | 8~5 | 20~800 | 30′-1°30′ | 1000 | 11 |

| Q11Y 8×2500 | 8 | 2500 | 14~30 | 20~600 | 30′-2° | 800 | 11 |

| Q11Y 8×3200 | 8 | 3200 | 12~30 | 20~600 | 30′-2° | 850 | 11 |

| Q11Y 8×4000 | 8 | 4000 | 10~25 | 20~600 | 30′-2° | 900 | 11 |

| Q11Y 8×5000 | 8 | 5000 | 10~25 | 20~800 | 30′-2° | 1000 | 15 |

| Q11Y 8×6000 | 8 | 6000 | 8~20 | 20~800 | 30′-2° | 1050 | 15 |

| Q11Y 12×2500 | 12 | 2500 | 12~25 | 20~800 | 30′-2° | 840 | 15 |

| Q11Y 12×3200 | 12 | 3200 | 12~25 | 20~800 | 30′-2° | 900 | 15 |

| Q11Y 12×4000 | 12 | 4000 | 8~20 | 20~800 | 30′-2° | 940 | 15 |

| Q11Y 12×5000 | 12 | 5000 | 8~20 | 20~1000 | 30′-2° | 1000 | 22 |

| Q11Y 12×6000 | 12 | 6000 | 6~20 | 20~1000 | 30′-2° | 1060 | 30 |

| Q11Y 16×2500 | 16 | 2500 | 12~20 | 20~800 | 30′-1°30′ | 840 | 22 |

| Q11Y 16×3200 | 16 | 3200 | 12~20 | 20~800 | 30′-1°30′ | 900 | 22 |

| Q11Y 16×4000 | 16 | 4000 | 8~15 | 20~800 | 30′-1°30′ | 940 | 22 |

| Q11Y 16×5000 | 16 | 5000 | 8~15 | 20~1000 | 30′-1°30′ | 1000 | 30 |

| Q11Y 16×6000 | 16 | 6000 | 6~15 | 20~1000 | 30′-1°30′ | 1100 | 37 |

| Q11Y 20×2500 | 20 | 2500 | 10~20 | 20~800 | 30′-3° | 900 | 30 |

| Q11Y 20×3200 | 20 | 3200 | 10~20 | 20~800 | 30′-3° | 950 | 30 |

| Q11Y 20×4000 | 20 | 4000 | 8~15 | 20~800 | 30′-3° | 1100 | 30 |

| Q11Y 20×5000 | 20 | 5000 | 8~15 | 20~1000 | 30′-3° | 1100 | 37 |

| Q11Y 20×6000 | 20 | 6000 | 6~15 | 20~1000 | 30′-3° | 1200 | 37 |

| Q11Y 25×2500 | 25 | 2500 | 8~15 | 20~800 | 30′-1°30′ | 900 | 37 |

| Q11Y 25×3200 | 25 | 3200 | 8~15 | 20~800 | 30′-1°30′ | 950 | 37 |

| Q11Y 25×4000 | 25 | 4000 | 6~12 | 20~1000 | 30′-1°30′ | 1100 | 37 |

| Q11Y 32×2500 | 32 | 2500 | 6~12 | 20~1000 | 30′-4° | 1000 | 55 |

| Q11Y 32×3200 | 32 | 3200 | 8~12 | 20~1000 | 30′-4° | 1100 | 55 |

| Q11Y 40×2500 | 40 | 2500 | 4~10 | 20~1000 | 30′-4° | 1200 | 55 |

| Q11Y 40×3200 | 40 | 3200 | 4~10 | 20~1000 | 30′-4° | 1200 | 55 |

E10S

|

Features: According to its features, E10S hydraulic swing beam shearing machinee is equipped with photoelectric encoder to display the position of back gauge. It can also set the shearing amount. Special single direction position indicating function and screw pitch deviation compensation table can ensure that the display position and the actual position are the same. It is also installed with time relay, soft limit and power memory, bringing great convenience for our customers. This CNC system owns highly cost-effective advantage. |

|

Main Function: 1. This system possesses 2 rows, 6×7 segment and LED display. 2. The unit of back gauge position is 0.1mm or 0.01 mm. 3. It owns screw pitch deviation compensation table. 4. Shearing count is available for this CNC system. 5. It has built-in time relay. 6. Inch or metric is optional. 7. Scale factor is free to set. |

E20

|

E20 CNC system for shearing machine is equipped with variable frequency drive to position the back gauge's location according to control characteristics of the shearer. The position precision can reach 0.1 mm. One hundred program steps ensure that complex workpieces can be finished once without one more adjustment. Special unidirectional positioning function can overcome the screw gap. The pitch deviation setting and a series of considerations can ensure machining accuracy. Automatic yield function can avoid the interference of the work piece and back gauge. We can choose either automatically search or power memory to remember the current position and to provide customers with more choices.

|

|

Main Function: 1. This system possesses 2 rows, 6×7 segment and LED display. 2. There is a positioning control of back gauge. The control accuracy reaches 0.1mm. 3. It owns screw pitch deviation compensation table and built-in time relay. 4. Inch or metric is optional. 5. Scale factor is free to set. 6. Shearing count is available for this CNC system. 7. The E20 CNC system has automatic concession function. |

E200S

|

E200S CNC system is formed based on E20 control function. It adopts high-definition LCD display and the latest electronic application technology. This system is typically used for controlling shearing machines. It features one-touch operation of function switch, friendly operation interface, more on-screen information for programming, easy and convenient automatic processing operation. Adopting patented drive control technology, CAN bus and our EDC series AC servo connection, its performance can be sufficiently played. Choice of Chinese and English, and inch / metric conversion are available to meet customers' needs form different countries.

|

|

Main Function: 1. This system possesses 240 × 128 LCD display. 2. With multiple steps programming, the program can run automatically featuring continuous positioning. 3. Automatic yield function can avoid the interference of the workpiece and back gauge. 4. Unidirectional positioning can eliminate the gap of the screw drive. 5. Inch or metric is optional. 6. The E200S CNC system features position compensation, power memory function and shearing count. 7. Reference-point automatic search is optional. |

RT200

|

RT200 shearing machine CNC system can be used for swing-type plate shear and guillotine shear.

|

|

Main Function: 1. This system possesses 64 × 128 LCD display and uses high-brightness blue display. 2. It has built-in PLD and FHG (Fourth Harmomc Generation). 3. Full Chinese or English fonts are clear and convenient. 4. Convenient switching of Chinese and English can meet customers' different needs. 5. With X axis full digital display, display accuracy can reach 0.01 mm. 6. X axis one-way positioning function ensures transmission accuracy 7. Automatic or manual positioning is optional with high control precision. 8. This system is programmable with ten steps (RT200 +). 9. Electrical assembly does not need to be equipped with time relay. The system is convenient and reliable. 10. The external switch self-diagnostic function can conveniently check and eliminate the circuit failure. 11. Intelligent error system can prevent action errors in the operation and protect the machine from easy damage. 12. The system comes with counting function. Customers can choose the plus or minus counting mode. 13. The electrical assembly does not require time relay. The system itself can control the shearing length with convenient and reliable operation. 14. X axis has soft limit function. 15. Control inverter is optional. 16. The external button is scalable to facilitate the needs of customers. |

SNC-18C

|

SNC-18C CNC system is a kind of economic and simple CNC system typically used for shearing machine. It is equipped with photoelectric encoder (100ppr to 500ppr) to control and monitor the position of back gauge of shearing machine. It also has limit, silk rod drive backlash compensation and power memory function. This system can be used for the replacement of general mechanical shears and upgrade of several other significant systems.

|

|

Main Function: 1. It features high brightness digital tube display of back gauge position and shearing count. 2. Teach-in function avoids the trouble of calculated transmission ratio or scale factor parameter, which greatly facilitates customers' use. 3. The screw backlash compensation can improve the machine accuracy. 4. Time relay is installed in the system convenient for shearing control. 5. This system does not need step-by-step programming. The back gauge single-step can be directly placed, which greatly reduces the technical training requirements of the machine operators. 6. Micro switch button and the numeric keypad contribute to extremely comfortable operation and longer panel service life. 7. Input and output state indicator is installed on the front of the panel to facilitate fault diagnosis. |

TR-360

|

TR-360 CNC Hydraulic Guillotine Shear and TR-310 CNC Hydraulic Pendulum Shear

|

|

Characteristics: 1. It features 65536-color TFT LCD and 800 × 480 high-resolution color LCD display. 2. Shear angle control is the unique characteristic of TR360 CNC hydraulic guillotine shear. 3. Each program has ten steps. It can be increased according to the actual situation. 4. The two systems have power memory function to ensure that the parameters and position values will not be lost. 5. They provide multilingual environment. 6. They features shearing workpiece count function and back gauge control. 7. The back gauge owns concession function. 8. The shearing gap control is also a unique feature of TR360 CNC hydraulic guillotine shear. 9. There is enough storage space for 200 programs. 10. The system comes with the program number, which is easy to operate. 11. Another feature of TR360 CNC hydraulic guillotine shear is that its axis can manually or automatically move. 12. They possess the function of searching for reference point. |

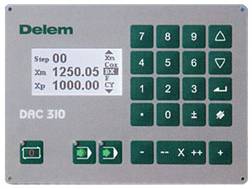

DAC-310

|

DAC-310 special CNC system for shearing machine adopts the latest electronic technology. Featuring compact structure and complete function, it can provide a set of general solutions for the back gauge and blade gap of shearing machine, and the shearing process control. There are mainly three back gauge axis control modes including servo motor control, double speed AC motor control and VVVF control.

|

|

Function: 1. This system possesses high-resolution LCD display with 275 × 48 pixels. 2. It features back gauge control, incision gap control and shear stroke control. 3. There is synchronized display of back gauge actual position and programmed value. 4. It owns shearing count function and panel mounting. 5. Max program step is up to 100. 6. Servo control / VVVF control / double speed AC motor control are available. |

DAC-350

|

This CNC system is a dedicated control system used for CNC hydraulic shearing machine. |

|

Function: 1. This system is suitable for automatic control for full-featured front feeding or back gauge control. 2. It adopts high-definition LCD display and menu-driven programming. 3. This CNC system can automatically calculate and control the shearing angle, blade gap and the shearing process. 4. It adopts the absolute position and relative position programming modes. 5. The system can automatically search for reference point and also can set the position of power memory. 6. There are several custom auxiliary signal outputs. 7. The unique hand wheel can facilitate adjustment of the machine. 8. It adopts modular structure, flexible definition or expansion X1-X2 synchronized feeding control and transmission Z axis control. 9. This CNC system has self-diagnostic program. 10. There are one-way positioning and bi-directional positioning available for customers. 11. It owns RS232 serial interface. 12. This system can set counting mode (count the increased and reduced). |

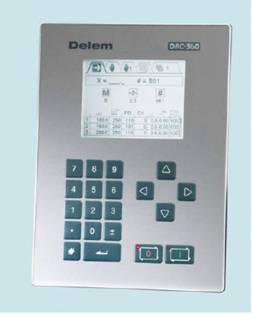

DAC-360

|

DAC-360 system provides a complete solution for shearing machine control, such as back gauge control, shearing angle control, shearing process control and shearing pressure control. In addition to the back gauge, DAC-360 system can automatically calculate the shearing angle and blade gap according to material properties and sheet thickness. In accordance with the sheet width, this system can automatically calculate the shearing process to maximize saving shearing time. This CNC system can realize control of the back gauge by servo, double speed motor or one-way direction output modes. Besides, according to the application, customers can also select single bilateral positioning of axis deviation correction table. The system can realize the full control of the clamping pressure and shearing pressure. The high brightness LCD display and concise programming interface provide operators with good human-computer interaction dialogue.

|

|

Function: 1. This system possesses 4.7 LCD display. 2. DAC-360 CNC system owns automatic control of back gauge, blade gap, shearing process and shearing angle. 3. It has the function of automatic count of shearing pressure. 4. There are 100 programs that each program has 25 steps. 5. I/O port flexible definition is available for this system. |

Tag: Mechanical Asymmetrical Plate Rolling Machine | Mechanical Asymmetrical Plate Rolling Equipment | Mechanical Asymmetrical Plate Bending Machine | Mechanical Asymmetrical Plate Bending Equipment

Tag: Mechanical Symmetrical Plate Rolling Machine | Mechanical Symmetrical Plate Rolling Equipment | Mechanical Symmetrical Plate Bending Machine | Mechanical Symmetrical Plate Bending Equipment