Description

Thick plate cut-to-length line is an upgraded model of the medium plate leveling production line. Steel mills produce steel plates with greater thickness and wider width. In order to adapt to this need, HB Machinery specially designed and manufactured this thick sheet cut to length line. Our company can adjust designs depending on customers' requirements. This thick plate cut-to-length line is often equipped with decoiler or uncoiler, double-end bead cutter and edge wire rolling machine to get high-quality four-trimming sheets.

Operation

Thick sheet cut to length line is a kind of special shearing equipment that levels the steel plate and shears it into clients' needed sizes. The main host of this equipment is composed of uncoiler, leveling machine, servo feeding cut-to-length, hydraulic shear, aggregate, etc. Thick plate cut-to-length line also has many accessory devices including buffer and guide, film, conveying and discharge device. When the thick sheet cut to length line is working, the uncoiler is in passive feeding state.

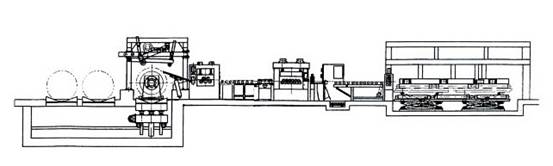

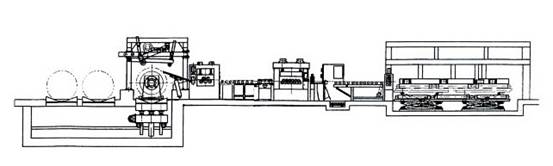

Structure Chart of Thick Sheet Cut to Length Line

Technical Parameters of Thick Plate Cut-To-Length Line

|

Item

|

Unit

|

Available Range

|

|

Thickness

|

mm

|

4~6, 2~8, 5~20, 6~25, 8~30

|

|

Standard Plate Width

|

mm

|

1500, 2000, 2200, 2500, 3000

|

|

Uncoiler Load

|

t

|

20, 30, 45

|

|

Leveling Precision

|

mm/m2

|

1.5, 2.0

|

|

Fixe-Length Precision

|

mm

|

±1.0

|

|

The Highest Line Speed

|

m/min

|

6, 10, 15, 18

|

|

Total Power

|

kw

|

160~420

|

HB Machinery is a professional manufacturer and supplier of thick plate cut-to-length lines in China. In addition to this thick sheet cut to length line, we also provide rolling machine, leveling machine, shearing machine, press brake, profile bending machine, etc. Due to our products' high quality, professional service and competitive price, our products are well received by customers all over the world.