Description

Mechanical shearing machine adopts advanced appliances (foot switch and manual switch) operation with little noise and convenient maintenance. This shearing equipment uses integral steel welded structure that is simple and easy to operate. Featuring attractive appearance and low energy consumption. This mechanical guillotine shear is broadly used in sheet metal processing plant, motor, electrical appliance, automobile manufacturing and other sheet metal processing plants. The mechanical shearing machine can shear a large scale of materials and improve labor efficiency. Manufactured from the superior quality raw materials, HB mechanical guillotine shears are highly acclaimed for quality and performance. Adopting the latest technology in the production process ensures high productivity and durability. HB Machinery is well renowned as the most preeminent mechanical shearing machine supplier in China.

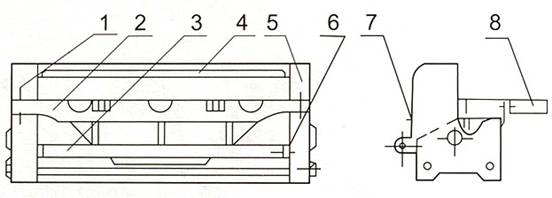

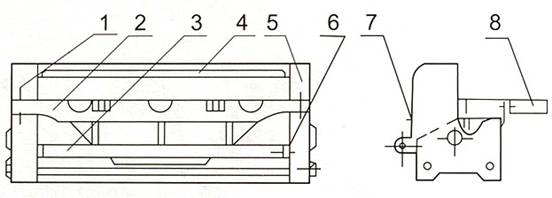

Components of Mechanical Guillotine Shear

-

Left Hand Column

-

Workbench

-

Front Beam

-

Rear Crossbeam

-

Right Hand Column

-

Tensioning Screw

-

Blanking Plate

-

Use screws to connect the prop rack into a whole and constitute framework structure.

Specifications

-

The mechanical guillotine shear adopts integral welded steel plate structure, hydraulic upper transmission and vibration to eliminate stress. This shearing equipment is famous for high strength and good rigidity. The mechanical shearing machine does shearing movement through the main oil cylinder, which can simplify the hydraulic system and make it run more stable. The top carrier swings like an arc around a fixed axis in the shearing process. Through the level effect, the machine affords small force, which can increase the usage life of shearing blade and the shearing machine. The mechanical guillotine shear owns compact structure that can adjust the amount of strokes of the top carrier and greatly improve work efficiency.

-

CNC system adopts full Chinese display that is easy to operate. Back gauge device possesses unidirectional and bidirectional positioning functions. It can effectively eliminate the screw gap. This mechanical shearing machine can avoid the interference between the back gauge device and workpiece, further reduce wear and improve positioning accuracy. Besides, the mechanical guillotine shear has functions of automatically or manually searching for reference point, power memory function and on-site protection of parameters, locations and programs. This shearing equipment also owns multi-step processing programming function that can realize disposable processing of various parts and improve production efficiency.

-

Mechanical shearing machine adopts security fence and electrical box interlock life safety protection device.

-

The mechanical guillotine shear employs advanced integrated hydraulic system with good reliability.

Technical Parameters

|

Model

|

Shearing Thickness

|

Shearing Width

|

Shearing Angle

|

Number of Stroke

|

Range of Back Gauge

|

Motor Power

|

Overall

Dimension

|

|

mm

|

mm

|

°

|

time/min

|

mm

|

kw

|

(L×W×H) mm

|

|

Q11-2×1000

|

2

|

1000

|

1°30'

|

75

|

350

|

1.5

|

1580×1450×1080

|

|

Q11-2×1300

|

2

|

1300

|

1°30'

|

75

|

350

|

1.5

|

1580×1450×1100

|

|

Q11-3×1200

|

3

|

1200

|

2°25'

|

55

|

350

|

2.2

|

1980×1500×1300

|

|

Q11-3×1300

|

3

|

1300

|

2°14'

|

55

|

350

|

3

|

2080×1550×1300

|

|

Q11-3×1500

|

3

|

1500

|

2°

|

55

|

350

|

3

|

2280×1550×1300

|

|

Q11-3×1600

|

3

|

1600

|

2

|

55

|

350

|

3

|

2280×1650×1300

|

|

Q11-3×2000

|

3

|

2000

|

2

|

25

|

500

|

5.5

|

3050×1650×1350

|

|

Q11-4×2000

|

4

|

2000

|

1°30'

|

25

|

500

|

5.5

|

3050×1900×1350

|

|

Q11-4×2500

|

4

|

2500

|

1°30'

|

25

|

500

|

5.5

|

3580×1900×1350

|

|

Q11-4×3200

|

4

|

3200

|

1°14'

|

20

|

500

|

7.5

|

4200×1960×1350

|

|

Q11-6.3×2000

|

6.3

|

2000

|

2°

|

40

|

500

|

5.5

|

3160×1760×1530

|

|

Q11-6×2500

|

6

|

2500

|

1°45'

|

40

|

500

|

7.5

|

3660×1760×1530

|

|

Q11-8×2500

|

8

|

2500

|

1°57'

|

45

|

500

|

11

|

3680×2160×1550

|

|

Q11-13×2500

|

13

|

2500

|

3°

|

30

|

600

|

15

|

3580×2300×2500

|

|

Q11-16×2500

|

16

|

2500

|

3°

|

30

|

700

|

18.5

|

3680×2600×2500

|