Description

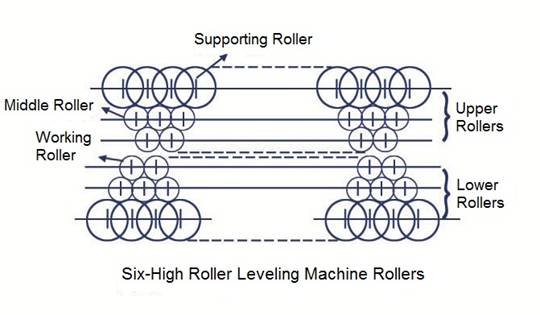

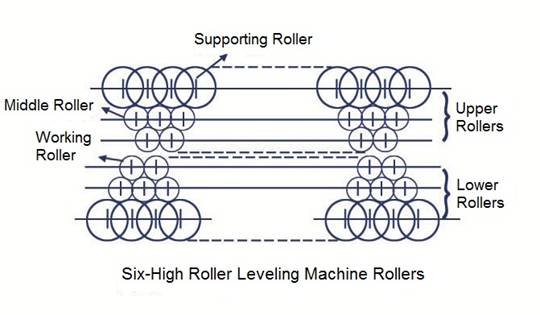

This six-high roller leveling machine, also known as six-roller straightening machine, is an upgraded model of the four-high roller straightening machine. The installation of a middle roller between the upper/lower leveling working roll and the support roll constitutes the six-high roller structure. The middle roller makes the supporting force of the support roll does not act directly on the working roll. This can avoid the four-high roller leveling machine leaving support roll indentation on the surface of sensitive materials when working. This six-roller straightening machine can also greatly maintain the surface state of processed materials. It is mainly used for leveling aluminum plate, stainless steel plate, copper, non-ferrous metal plate and different metal composite plates. The leveling roller force is distributed evenly. This roller leveling machine features rigid structure, small bending deformation and high leveling precision. It is applicable for leveling high precision plates. This six-roller straightening machine is an essential device for leveling aluminum.

Main Parts

-

The long carrier roller along with multiple sets of support rolls constitutes the six-high roller structure.

-

There is a gap removal device for this six-high roller leveling machine.

-

The end processing of leveling roller and the carrier roller includes precise grinding, hard chrome plating and precise polishing.

-

The surface of the leveled plate features good quality. The six-roller straightening machine works with smooth transmission and low noise.

-

The heat treatment process, the structure and adjustment of the distribution box and lubrication system are all similar to the four-high roller leveling machine.

-

For leveling roller and carrier roller, GCr15, 9CrSi or 9Cr2Mo are optional.

-

The universal joint shaft of this six-roller straightening machine is made up of alloy structural steel materials (homemade).

-

We provide TR type and ZLY hardened reducer for customers.

Structure Chart of Six-High Roller Leveling Machine

Technical Parameters of Six-Roller Straightening Machine

|

Model

|

Max. Leveling Thickness

|

Max. Leveling Width

|

Min. Leveling Thickness

|

Distance between Working Rollers

|

Diameter of Working Rollers

|

Number of Working Rollers

|

Leveling Speed

|

Main Motor Power

|

|

|

mm

|

mm

|

mm

|

mm

|

mm

|

|

m/min

|

kw

|

|

W43-2×800

|

2

|

800

|

0.6

|

50

|

48

|

21

|

6

|

7.5

|

|

W43-2×1300

|

2

|

1300

|

0.6

|

55

|

50

|

19

|

10

|

55

|

|

W43-3×1600

|

3

|

1600

|

0.8

|

70

|

65

|

15

|

10

|

45

|

|

W43-3×2500

|

3

|

2500

|

0.8

|

80

|

75

|

19

|

10

|

37

|

|

W43-6×2000

|

6

|

2000

|

1.5

|

100

|

95

|

13

|

8.6

|

45

|

HB Machinery is a professional manufacturer and supplier of six-high roller leveling machines in China. In addition to this six-roller straightening machine, we also provide rolling machine, shearing machine, press brake, profile bending machine , etc. Due to high quality, professional service and competitive price, our products are well received by customers all over the world.